Location:Home > Company News

100 FAQs of pump (Theme Two )

2017-07-09

Fire pump is to fire fighting truck what heart to is to body, playing an very important role. Huaqiu fire pump builds domestic leading brand via its professional technology. Its efficient and low-energy flow components benefit from the perfect hydraulic model. The compact and convenient structure is derived from the advanced design concept.The reliable and smooth operation is the crystallization of the advanced process equipment.

There are 100 FAQs for you to study water pump.

Questions 21 - 30:

21. What is rotor's unbalanced vibration?

There exists an unbalanced particle integrated into two forces that are not in a straight line, with same size and opposite direction.

22. What are the causes of imbalance in the impeller?

1. The manufacturing error: uneven materials dense; uneven heat treatment of different shaft and roundness;

2. Incorrect fabrication: The centerline of the assembly part is not coaxial with the axis;

3. Deformation of impeller: uneven wear.

23. What is the cause of excessive pump power consumption?

1)The total lift does not match the lift of the pump;

2) The density and viscosity of the medium are not in accordance with the original design;

3)The rotational part has friction with the fixed part;

4)Impeller mouth ring wears;

5)Improper installation of seal or mechanical seal.

24. What is cavitation?

Cavitation is a special physical phenomenon of liquids. In the process of operation. The pump can reduce the pressure of the local position of the pump to the water under the corresponding temperature ( vaporization pressure ). The water starts to vaporize and generates a large number of bubbles. The bubble moves along with the water flow and moves to the higher part of the pressure, and then quickly coagulate and collapse. The formation of steam bubbles in the water flow in the pump involves the physical, chemical phenomena and the noise, vibration and erosion of the flow components, which is called cavitation of water pump.

25. What are the phenomena of cavitation caused by pump?

1)Noise and vibration: Because of the pump cavitation, a continuous burst in the high pressure zone produces a strong water hammer, which produces noise and vibration. The first production of cavitation can be detected according to noise.

2)Corrosion damage of overcurrent parts: When the pump is working under cavitation conditions, the pump overflow parts will be corroded in some places. The bubble bursts with a high frequency shock (600~25000HZ ) with pressure of 49Mpa, resulting in mechanical denudation of metal surface. And because of the release of heat in vaporization and hydrolysis produced by thermo-cell action, the produced oxygen oxidizes the metal and causes chemical corrosion.

3)Performance degradation: The exchange of energy in impeller during pump cavitation is disturbed and destroyed. The performance of the exterior characteristics is the decrease of flow/lift curve, flow/power and flow/efficiency curves. In severe case, the fluid flow in the pump can be interrupted and unable to work.

26. How to prevent cavitation during operation?

1)Reduce the suction height;

2)Reduce the suction loss hc, so we can try to increase the diameter of the pipe and minimize the length of the pipe, the bend and the attachment.

3)Prevent long running on large flow;

4)Under the same speed and flow rate, double suction pump is adopted to reduce the inlet velocity and the pump is not easy to cavitation;

5)When the pump has cavitation, the flow rate should be small or slow.

6)For pumps operating under harsh conditions, cavitation erosion can be used to avoid cavitation damage.

27. What is the types of pump?

The pump can be divided into three categories: 1) vane pump, 2) volumetric pump, 3) other types of pumps.

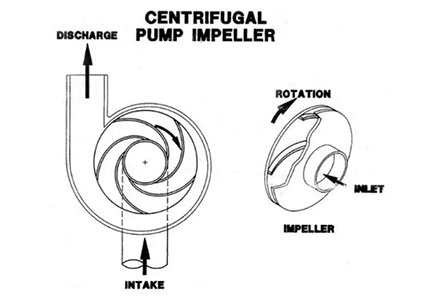

28. What is a vane pump?

The pump that conveys the liquid through the interaction of blades and liquids , such as centrifugal pump, axial flow pump and mixed flow pump.

29. What is volumetric pump?

In the process of changing the volumetric volume of the pump in a periodic manner, the volumetric pump conveys power to transported liquid by the periodic change of action and displacement, increasing the pressure to the required pressure value. 1) reciprocating pumps, including piston pumps, plunger pumps, diaphragm pumps, etc. 2) rotor pump, including gear pump, screw pump, rotary piston pump, slide pump, crankshaft pump, etc.

30. What are the main performance parameters of pumps?

Main includes: flow, lift, cavitation residual, speed, power and efficiency.